First Sample cont.

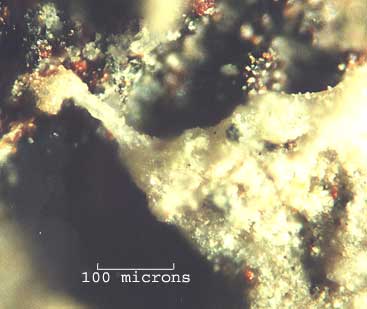

Optical microscopy showed the deposit to be composed of discrete

regions of different compounds – hence the mottled appearance. Although

there were some large crystalline inclusions, each of these regions were mostly

an agglomerate of fine crystalline structures. The regions could be generally

listed as iron oxides with elemental iron, silica, calcium compounds and some

fibrous plant material. In order to confirm this assessment, the first sample

was analysed in an SEM. The results of this test can be seen here: ANALYSIS

In general, there are two naturally occurring oxides of Iron:

Ferric oxide, Fe2O3, occurs as Haematite in the anhydrous form and as Limonite, 2Fe2O3,3H2O, as the hydrate. Rust is mainly hydrated ferric oxide. Haematite occurs in black metallic crystals as ‘specular iron’ and can also take on a dull red appearance when finely reduced. It is only slightly magnetic and conductive.

Ferroso-ferric oxide, Fe3O4, is the most stable oxide of iron. It has a black metallic lustre and occurs as Magnetite, the lodestone of the ancients. Importantly for the present investigation, it forms when iron is heated in air or steam and (as its name implies) it is strongly magnetic. It is also slightly conductive.

Iron oxide regions constituted about 80% of the glaze. They appeared as a dark red/black amorphous crystalline structures with small quantities of interspersed reflective black globular beads. These latter appeared to be reduced particles of elemental iron that had melted and then solidified by surface tension into rounded forms. A prominent and isolated example can be seen in Fig 3. The limited quantity of elemental iron could not account for the degree of magnetic susceptibility of the specimen. The magnetic properties were, therefore, assumed to be largely due to the Magnetite. Dispersed across the surface of the specimen, but showing up strongly on the oxide, were numerous fragments of calcium compounds and what appeared to be quartz (an hexagonal crystalline form of silica).

Although both oxides are slightly conductive, the H-glaze sample in my possession exhibited very little conductivity and that on only about 1% of the surface. This was probably due to the other impurities present but the observed finely reduced crystalline structure could also have been a contributory factor.

Silica

Silica (Silicon dioxide, SiO2) appears to exist in fine crystalline form as quartz, tridymite and/or cristobalite. Curiously, it was widely interspersed between the regions of iron oxide but it was particularly difficult to account for its presence on the surface of the deposit. However, its presence provided us with a most remarkable observation.

Fig 5

In areas where the two were in close proximity, the silica seemed to have been heated to melting point by heat from the iron oxide. An example can be seen in Fig 4. Two clearly defined regions abutted one another. One (at the top) was Iron oxide; the other was principally composed of silica. This latter region had a compacted crystalline appearance except where it bordered the former. Along this interface, it appeared to have melted and consolidated. Furthermore, at three points, this softened material had remained attached to the darker ferrous body causing it to become distended as the surrounding material had shrunk into the melt. Such behaviour is uniquely characteristic of melting, which inevitably implied heating.

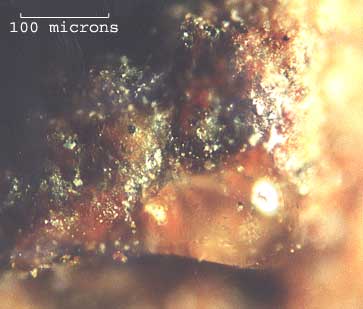

Other examples suggesting heating could be found. Fig 5 shows a droplet of silica glass that had formed and ‘wetted’ the surface of the iron oxide. The area surrounding this droplet was also coated in a glaze of consolidated silica. Note that it is possible to see through the droplet and Silica glaze to the surface beneath. It was also observed that silica glass of this type existed only in contact with the iron oxide. It could not be found anywhere else on the sample.

Also, there were areas where bubbles of silica glass had been formed by gasses (and presumably steam) that had erupted through the heated oxide layer. The shattered remains of such bubbles were present on the sample but two intact examples can be seen in fig 6. Note the small fragments of silica/chalk adhering to the smooth surface of these features. Such surface contaminants could have been isolated and stuck on the surface of the bubbles as they expanded. Their presence can not be accounted for if the bubbles were the result of a water based corrosion product, as has been suggested.

Silica glass softens at a much higher temperature than ordinary glass - about 1500ºC – about the same temperature at which iron melts.

Fig 6

Calcium Compounds

In view of the abundance of chalk in the area, it may not seem

surprising to have found fragments in the H-glaze. However, its presence on

the surface of the deposit is puzzling. Apart from the dusting of microscopic

crystals that covered the glaze, there were numerous inclusions of larger

agglomerates of both chalk and Silica (e.g.. top-left in Fig 6). As these

were fused to the surface of the sample, they were unlikely to have been the

result of contamination. It was also noted that some of the small crystals

were adhering to the surface of the silica glass (Fig 6). If the H-glaze had

simply been deposited on the ground, how did the calcium (and Silica) get

on the surface of the glaze?

Fibrous Plant Material

There were what appeared to be fragments of plant tissue incorporated into

the surface of the H-glaze. Only two were clearly identifiable and they were

heavily stained by the surrounding material indicating that the sample had

been damp at some time. There was insufficient material to deduce much more.